Porsche Classic

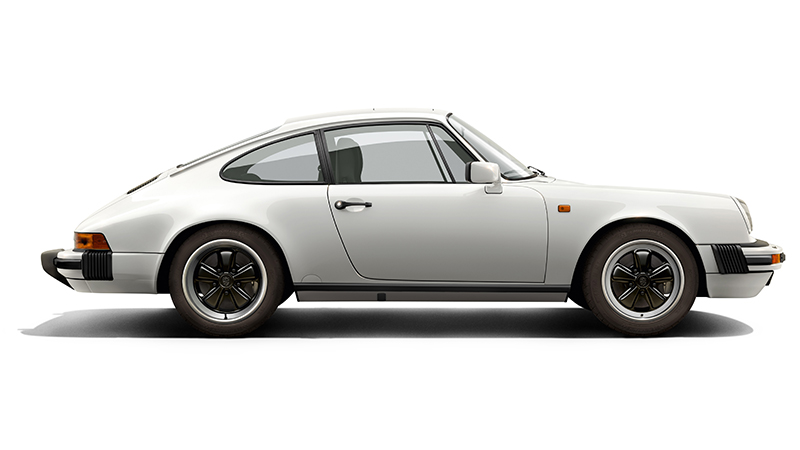

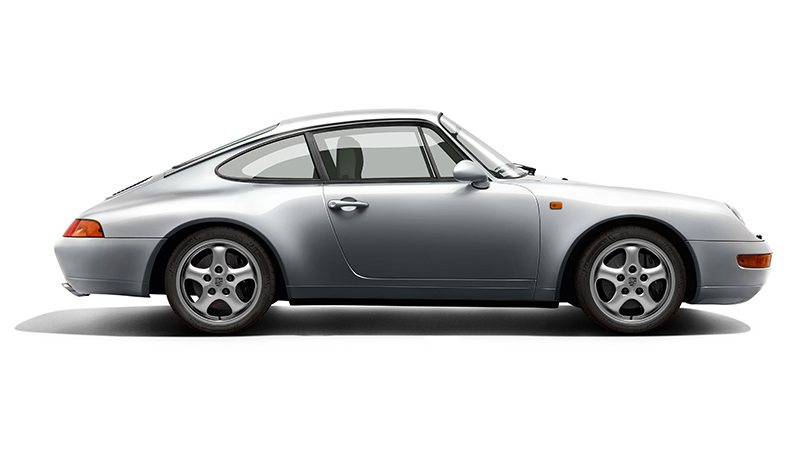

Models

Porsche Classic Parts Explorer

Porsche Classic Partner

Porsche Classic Online Newsletter

Caretakers of Dreams

Porsche Classic Live

Share your most beautiful pictures under the hashtag #porscheclassic and become part of